Taking care of the challenges on the IT side of the end-to-end solution, Zehntech implemented the IIoT with our US-based customer and GE Automation in the Oil and Gas domain. The Asset-Monitoring Module, Alert Module, and Reporting Module (which included oil wells, gas pipelines, oil tanks, and compressors) were moved into a single platform using GE Predix cloud and GE IIoT field devices.

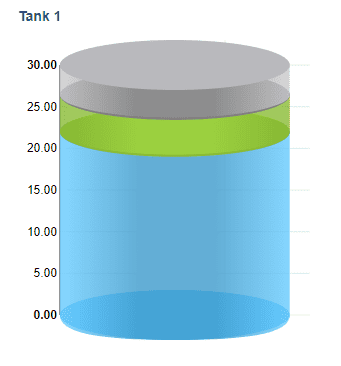

Currently, the field devices stream live data with intervals of 10 seconds from 8 different assets with 5-6 different data matrices, like oil flow, oil level, tank temperature, gas pressure, vibrations, alerts, etc.

The goal was to build a single IIOT app (using NodeJS, AngularJS, and Google Polymer) and deploy the GE Predix cloud for real-time monitoring, alerts, and predictive analytics. Right now, we are implementing a machine learning predictive module to predict tank level, machine failure, and optimized gas injection for maximizing oil production.

During the project, we configured field agents to use MQTT to transfer sensor data to the Predix Time series database. Next, we aggregated the data to calculate actionable information.

For example:

Based on the oil flow rate, tank number 4 will be full in 1 hour and 39 Minutes. Based on the gas pressure, we can predict if the gas compressor is going down.